Blog

Custom XLPE Foam Packaging From Design to Delivery

Discover XLPE Foam

When it comes to innovative foam solutions, few materials compare to the versatility and durability of cross-linked polyethylene (XLPE) foam. At AFP, we specialize in leveraging the unique properties of XLPE foam to build custom solutions for any industry.

First let’s take a look at the properties and benefits of XLPE foam. Then we’ll dive into a project we completed for one of our clients, Globex Performance.

The Advantages of XLPE Foam

XLPE foam is a closed-cell foam characterized by its fine, uniform cell structure. This material is known for its strength, flexibility, and resilience, making it an ideal choice for several applications, including packaging, insulation, and cushioning.

Why might XLPE foam be the solution for your business?

- Durability: Resistant to impact, moisture, and chemicals, ensuring longevity and performance.

- Lightweight: Provides excellent protection without adding significant weight.

- Flexibility: Easily conforms to various shapes, making it perfect for custom packaging solutions.

- Insulation: Offers superior thermal and acoustic insulation properties.

The AFP Difference

We pride ourselves on delivering tailored foam solutions that meet our clients’ unique needs. Our expertise in working with XLPE foam enables us to create products that both protect and enhance our clients’ offerings.

Our process includes:

- Consultation: Understanding the specific requirements and constraints of each project.

- Design: Crafting innovative blueprints that leverage the strengths of XLPE foam.

- Production: Employing advanced manufacturing techniques to produce high-quality products.

- Quality Assurance: Rigorous testing to ensure each product meets our standards.

Case Study: Custom XLPE Foam Packaging for Globex Performance

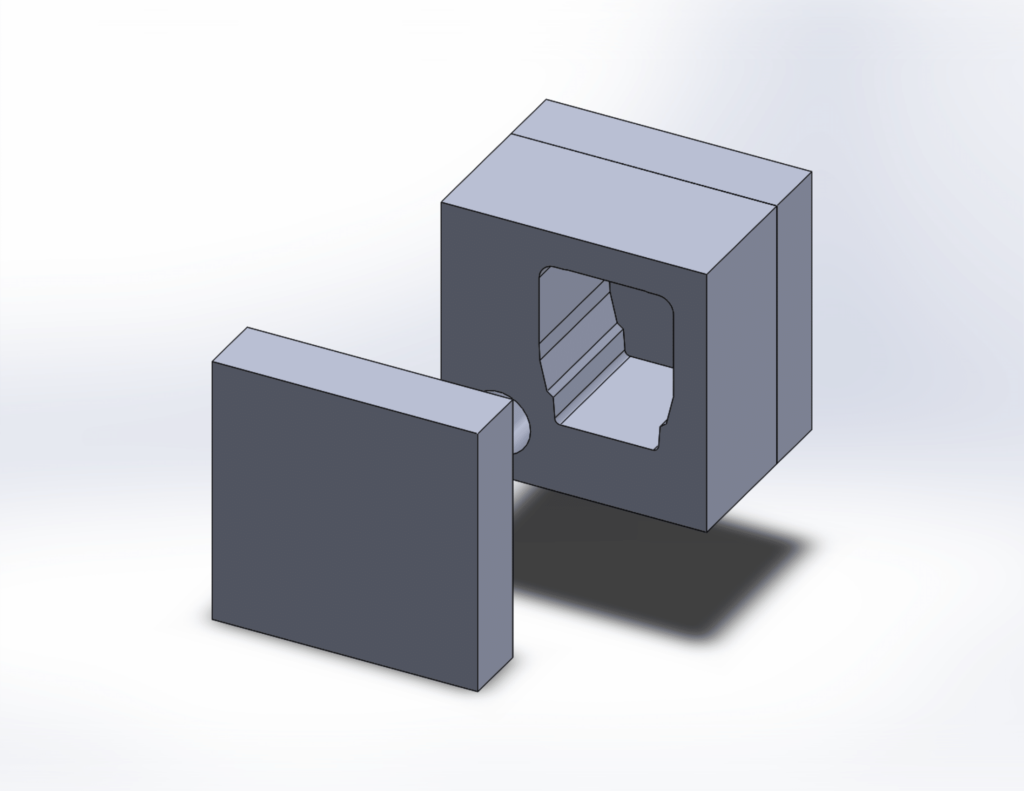

When Globex Performance, a manufacturer of automotive parts, approached us with a need for specialized packaging for their custom shift knobs, we knew XLPE foam was the solution. Known for their ergonomic shape and sleek aesthetic, these shift knobs required packaging that would protect them during transit and amplify their presentation.

Project Goals:

- Protection: Ensure the shift knobs are protected from impact and vibration during shipping.

- Presentation: Create a visually appealing unboxing experience that reflects the premium quality of the product.

- Customization: Design the foam to snugly fit the unique shape of the product.

Our Approach:

- Design Consultation: We collaborated closely with the Globex Performance team to understand their packaging needs and the specific dimensions and features of their shift knobs.

- Custom Foam Design: Our design team developed a custom XLPE foam insert that securely held the shift knobs in place. The foam’s closed-cell structure provided excellent protection against impact and vibration.

- Elevated Presentation: The foam was precision-cut to fit the shift knobs perfectly, ensuring a trim and professional appearance.

Results:

Globex Performance was thrilled with our premium XLPE foam packaging. It received positive feedback from both our client and their customers.

“Working with AFP on the custom packaging for our shift knobs was a fantastic experience. Their expertise in XLPE foam design ensured our products were well protected and professionally presented.” -Michael N., Co-Owner, Globex Performance

Is XLPE Foam Right for Your Project?

If you think your business could benefit from XLPE foam, contact us today to request a sample and discuss how we can create a custom foam solution for you.